Latest technology, and an amiable working environment characterize our world-class infrastructure. The fully automated plant is equipped with Lohia made automatic cutting and stitching machine for enhanced performance and productivity. Presently, we have production capacity of 40 lakh bags per month.

Our teams of qualified technical and non-technical staffs are master of their trades and have vast experience in the field. They are given regular training to keep abreast with the latest technological developments in the industry.

We also have an in-house laboratory equipped with the most advanced testing facilities for FIBC bags and PP/HDPE sacks. The latest testing equipment guarantees products that match international standards of quality and reliability. Integrating our resources and technology, we can efficiently meet all the bulk and contingency requirements of our worldwide clients.

| Extrusion | We produce 900 kgs per hour of Polypropylene tapes of various weights and strengths with two Lohia tape lines |

|---|---|

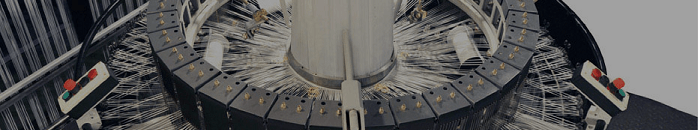

| Looms | 50 high speed Lohia looms (Six Shuttle) to produce fabric of any width and weight |

| Belt Weaving | Four needle looms (20 Heads) |

| Lamination | 90 mm Extrusion Coating Plant with a maximum lamination width of 2.2 meters |

| Fabric Cutting | 5 cutting machines |

| Belt Cutting | We have Automatic Belt/Webbing Cutting machines |

| Printing | 3 printing machines |

| 4 colour machine (62″ x 82″) | |

| Four six color/four color roto gravure | |

| Printing Machine for Online Printing of Small Bags | |

| Auto Cutting | 2 Auto cutting and stitching machine. |

| Balling Press Machine | 2 No’s |

| D.G Set | 1 No’s |

| Air Compressor | 4 No’s |

| Cooling Tower | 2 No’s |

| Testing Lab | We have equipments to check the breaking strength of tapes and also ultraviolet testing of tapes. Other tests performed by us as per Indian and International standards include Elongation Testing, UV Testing, Load Test, Dart Impact Test, Co-efficient of friction testing (slip and anti-slip), Air Preamblity test, UN Testing etc |